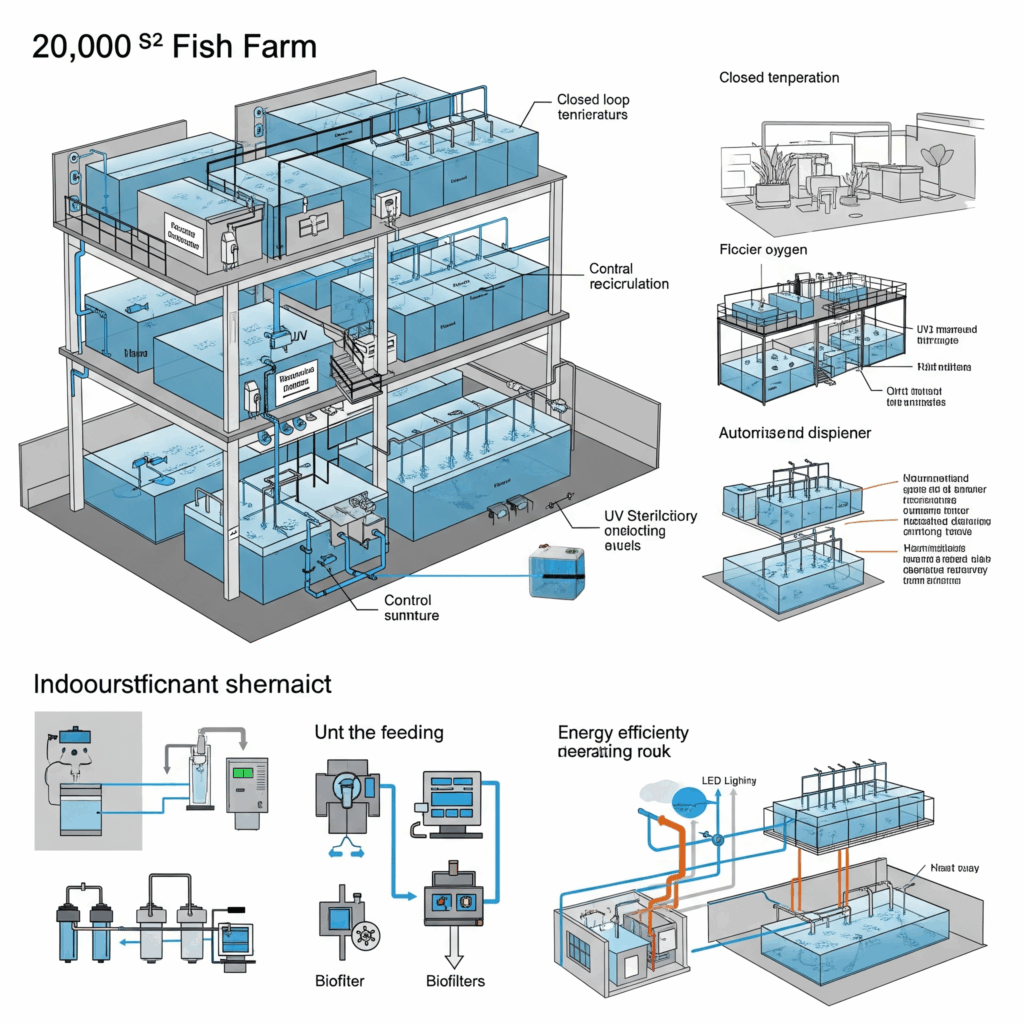

Designing a 20,000 square foot indoor fish farm, especially a state-of-the-art one, is a complex undertaking that heavily relies on Recirculating Aquaculture System (RAS) technology. The cost analysis and equipment list will vary significantly based on the specific fish species, desired production volume, level of automation, and chosen technology providers.

The overview of the essential equipment and a general framework for cost analysis. Please remember that the figures provided are estimates and actual costs will require detailed quotes from suppliers and specific engineering designs.

Equipment List for a 20,000 sq ft Indoor Fish Farm (RAS)

I. Fish Rearing & Containment:

- Fish Tanks:

- Grow-out Tanks: Large, round or rectangular tanks, often fiberglass or high-density polyethylene (HDPE). Size and number depend on species and stocking density.

- Nursery/Hatchery Tanks: Smaller tanks for larvae and fingerlings.

- Quarantine Tanks: For new or diseased fish.

- Harvest/Holding Tanks: For preparing fish for market.

- Tank Liners/Coating: Food-grade materials for concrete tanks if not using pre-fabricated ones.

- Piping and Fittings: Extensive PVC or HDPE piping for water circulation, drains, and aeration lines.

II. Water Treatment & Filtration (RAS Core): - Mechanical Filtration:

- Drum Filters (or Micro-screen Filters): To remove solid waste (feces, uneaten feed). Crucial for reducing organic load.

- Settling Tanks/Clarifiers: For initial removal of heavier solids.

- Biological Filtration (Biofilters):

- Moving Bed Biofilm Reactors (MBBRs): Tanks filled with plastic media where beneficial bacteria grow to convert ammonia and nitrite into less toxic nitrates.

- Fixed-Bed Biofilters: Media fixed in place.

- Trickling Filters: Water cascades over media.

- Degassing Units/Stripping Towers: To remove dissolved gases like CO2 and nitrogen from the water.

- Oxygenation System:

- Oxygen Generators (PSA or Liquid Oxygen Tanks): To produce or store pure oxygen.

- Oxygen Cones/Diffusers/Aeration Stones: To efficiently dissolve oxygen into the water.

- Air Blowers/Compressors: For general aeration.

- UV Sterilizers (or Ozone Generators):

- UV Sterilization Units: To kill bacteria, viruses, and parasites in the water, preventing disease spread.

- Ozone Generators: Alternative or supplementary disinfection, requiring careful monitoring and destructors.

- Pumps:

- Water Pumps: High-volume, energy-efficient pumps for circulating water throughout the RAS.

- Sludge Pumps: For removing solids from filtration units.

- Water Heating/Cooling System (HVAC):

- Heat Exchangers/Boilers/Chillers: To maintain optimal water temperature for the specific fish species.

- Insulation: For tanks and building to minimize energy loss.

III. Environmental Control (Building & Climate): - Building Construction/Renovation: Insulation, specialized flooring (sloped for drainage), ventilation.

- Ventilation & Dehumidification System: To control humidity and air quality within the building, preventing condensation and mold.

- Lighting: Energy-efficient LED lighting, potentially with programmable schedules.

- Backup Power Generator: Essential to ensure continuous operation during power outages.

- Security System: Cameras, access control.

IV. Feeding System: - Automated Feeders: Programmable feeders to deliver precise amounts of feed at scheduled intervals. Reduces labor and waste.

- Feed Storage Bins/Silos: Climate-controlled storage for bulk feed.

V. Monitoring & Control Systems (Automation): - Water Quality Monitoring Probes: Sensors for Dissolved Oxygen (DO), pH, temperature, ammonia, nitrite, nitrate.

- Centralized Control System (SCADA/PLC): Computerized system to monitor all parameters, control equipment, and trigger alarms.

- Alarm System: SMS, email, or visual alarms for critical parameter deviations.

VI. Harvesting & Processing Equipment: - Fish Graders: Sizing fish for market.

- Nets, Buckets, Handling Equipment: For transferring and harvesting fish.

- Ice Machines/Chillers: For post-harvest cooling and preservation.

- Processing Tables/Stations: For gutting, filleting, etc. (if done on-site).

- Packaging Equipment: Vacuum sealers, scales.

VII. Waste Management: - Sludge Collection Tanks: For storing concentrated solid waste.

- Sludge Dewatering System: To reduce volume of waste.

- Nutrient Recovery System (Optional): Technologies to capture nutrients from wastewater for use as fertilizer.

VIII. Ancillary Equipment & Supplies: - Laboratory Equipment: For detailed water quality testing (test kits, spectrophotometer).

- Safety Equipment: First aid, emergency showers, PPE (personal protective equipment).

- Cleaning Supplies: Brushes, hoses, disinfectants.

- Fish Feed: Initial stock of high-quality feed.

- Fish Stock: Fingerlings or juveniles to start.

- Office Equipment: Computers, communication systems.

Cost Analysis Framework (Estimates for 20,000 sq ft)

It’s extremely challenging to give precise costs without detailed design, but here’s a rough breakdown and very broad estimates for a highly advanced, state-of-the-art 20,000 sq ft RAS facility, aiming for that $8 million capital campaign target.

Disclaimer: These are highly speculative figures for illustrative purposes only. Actual costs can vary by a factor of 2x or more depending on quality, location, supplier, and specific design choices.

I. Capital Expenditures (CapEx) – Estimated Range: $5 Million – $15 Million+

This is the big chunk, likely what your $8 million campaign primarily targets. - Building Construction/Renovation:

- Estimate: $1.5 million – $5 million (Highly variable based on existing structure, new build, insulation, specialized flooring, ventilation infrastructure). For 20,000 sq ft, at $75-$250/sq ft.

- Fish Rearing Systems (Tanks, Piping):

- Estimate: $1 million – $3 million (Depends on tank material, size, number, and complexity of plumbing).

- Water Treatment & Filtration (RAS Core Equipment):

- Estimate: $1.5 million – $4 million+ (Drum filters, biofilters, oxygenation, UV, pumps are significant investments. High-end automation drives costs up).

- Environmental Control (HVAC, Backup Power):

- Estimate: $500,000 – $1.5 million (Large-scale climate control, dehumidification, and a robust backup generator are essential).

- Automated Feeding System:

- Estimate: $100,000 – $500,000 (Centralized storage, automated delivery lines).

- Monitoring & Control System (Automation/Sensors):

- Estimate: $100,000 – $700,000 (Sophisticated PLC/SCADA systems with numerous sensors).

- Waste Management & Processing Equipment:

- Estimate: $200,000 – $1 million (Sludge handling, basic processing equipment).

- Initial Fish Stock (Fingerlings/Juveniles):

- Estimate: $50,000 – $200,000 (Varies greatly by species and initial stocking density).

- Engineering, Design, & Consulting Fees:

- Estimate: $200,000 – $800,000 (Crucial for proper RAS design and avoiding costly mistakes).

- Permitting & Licensing Fees:

- Estimate: $10,000 – $100,000 (Varies by state/local regulations).

- Contingency (10-20% of total CapEx):

- Estimate: $500,000 – $2 million (Always factor this in for unexpected costs).

Total Estimated Capital Expenditure: $5,000,000 – $15,000,000+

An $8 million capital campaign would place Finns Fishery Corp in the range for a well-equipped, state-of-the-art facility, but likely not the absolute most expensive, fully automated, ultra-high-density system.

II. Operating Expenditures (OpEx) – Annual Estimated Range:

These are the ongoing costs once the farm is operational. - Feed: (Largest ongoing cost) Varies by species, feed conversion ratio (FCR), and production volume.

- Estimate: $500,000 – $2,000,000+ per year

- Electricity: (Significant for pumps, HVAC, lighting)

- Estimate: $100,000 – $500,000+ per year (Highly dependent on energy efficiency and local rates).

- Labor: (Skilled technicians, managers, processing staff)

- Estimate: $200,000 – $800,000+ per year (For a team of 4-10+ people depending on automation level).

- Water & Wastewater Treatment Chemicals: (For water quality maintenance)

- Estimate: $10,000 – $50,000 per year

- Maintenance & Repairs: (Equipment wear and tear)

- Estimate: $50,000 – $200,000 per year

- Insurance:

- Estimate: $10,000 – $50,000 per year

- Marketing & Sales:

- Estimate: $50,000 – $200,000 per year

- Biosecurity & Veterinary Costs:

- Estimate: $5,000 – $30,000 per year

- Depreciation: (Accounting for equipment lifespan)

- Estimate: Varies, but significant given high capital investment.

To get accurate figures for Finns Fishery Corp’s $8 million target, they would need to: - Define Species & Production Goals: What fish will they raise? How many pounds/tons per year?

- Develop a Detailed RAS Design: Work with aquaculture engineers to create blueprints.

- Obtain Multiple Quotes: Get competitive bids from equipment suppliers and contractors.

- Create a Comprehensive Business Plan: This would include detailed financial projections, market analysis, and a staffing plan.

A state-of-the-art 20,000 sq ft indoor fish farm is a substantial investment, but it offers significant advantages in terms of control, sustainability, and consistent production for high-value markets.